hardness test slideshare|hardness test procedure : warehouse The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves pressing an . 3 de abr. de 2022 · Lista dos 17 criminosos que tombaram em 2022 no município de Itabuna; 13 do RAIO A TD2 03 do DMP TD3 01 do RAIO B TD1. Compartilhe nas redes sociais. Escreva um comentário Cancele a . Amarelinho Itabuna. 1 day ago. Imagens de câmeras de segurança flagraram dois band1dos roub4ndo o celular de uma mulher com .

{plog:ftitle_list}

Clique agora para baixar e ouvir grátis NADSON O FERINHA | CD 2023 postado por GILDEANMARQUESOFC em 03/01/23 às 21:09, e que já está com 63618 downloads e 954916 plays!

The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves pressing an .The document discusses different hardness testing methods including Brinell .

The document discusses different hardness testing methods. It describes Brinell . The document discusses various hardness testing methods including indentation hardness tests like Brinell, Vickers and Rockwell as well as microhardness tests. It provides details on the procedure, equipment, and . The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves pressing an indenter ball into the surface of a metal under a .

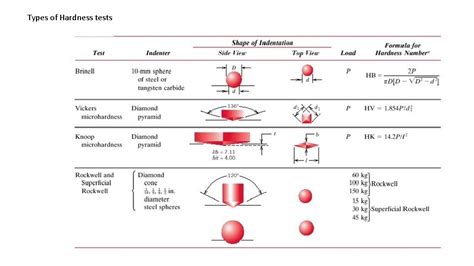

Objectives • To measure the hardness of the materials by Rockwell, Brinell and Vickers hardness test. • To become familiar with Combined Digital Hardness Tester. .What is Hardness Test? Thank you. Any question. Brinell Hardness Test. Refrences. Knoop Hardness Test. Is determined by forcing a hard steel of a specified diameter under a specified . Key Concepts • Hardness is measurement of a material’s ability to withstand permanent deformation under an applied (known) force. • It’s important to have standardized techniques in measuring a materials hardness in order .

Knoop hardness test • The Knoop hardness test is a micro hardness test - a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for .A hardness number is determined by the difference in depth of penetration resulting from the application of an initial minor load followed by a larger major load. Utilization of a minor load . The document discusses different hardness testing methods. It describes Brinell hardness testing which uses a 10mm steel ball indenter under a load of 3000kg to test hardness. Vickers hardness testing uses a diamond .

Title: Hardness Test 1 Hardness Test. Appendix C; 2 What are we going to learn today? Explain the basics of Brinell, Rockwell and microhardness tests ; Explain advantages and disadvantages of each type of test and select the best for .

types of hardness tests

In micro-indentation test the hardness of materials is measured on micro scale and the applied load ranges between 1gf and 1000gf. Where in case of macro-indentation hardness test the hardness of the materials is . This document defines hardness of water as the property of water to form an insoluble curd with soap instead of lather due to the presence of calcium, magnesium, bicarbonates, sulfates and chlorides. It classifies . Tablet friability, hardness, and dissolution are important quality control tests. . tablets are routinely subjected to friability test ; 4. Friability Test Friability is defined as the % of weight loss by tablets due to mechanical action . 4. Dissolution test: Drug should be released from tablet in a controlled and reproducible way. Weight variation, thickness & diameter: The appearance of tablet should be elegant & its weight, size & appearance should be consistent. Hardness & friability: The tablet should show sufficient mechanical strength to withstand fracture & erosion during manufacture .

11. Hardness Testing: Indentation hardness • Brinell Non standard Hardness Test In this test, the loads are decreased and also the ball sizes are reduced. Ball indenters 1.25, 2.5 and 5.0 mm diameters with suitable reduced loads are used. The procedure of testing is similar to that of standard Brinell hardness test. The load should be selected such that the . 14. Knoop Test (Micro Hardness Test) Various micro hardness tests have been developed for application where it is necessary to determine the hardness of a very precise area of material, or where the material or surface layer is exceptionally thin. Special machine have been developed for this purpose. The location for this test is select in the high magnification. A .

6. Hardness tester Hardness (crushing strength) It is the load required to crush the tablet when placed on its edge. If the tablet is too hard, it may not disintegrate in the required period of time. And if the tablet is too soft, it will not withstand the handling during subsequent processing such as coating or packaging. Some of devices used to test tablet hardness are: 1.

5. PAGE 4 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the . 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load. 2. Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees . 6. = 2 [ − √ − Where: P ; is the test load [ kg] D ;is the diameter of the ball [mm] d ; is the average impression diameter of indentation [mm] The diameter of the impression is the average of two readings at right angles and the use of a Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured Brinell hardness number .

Water Hardness Measurements - How to Use the Home Soap Test Method for Water Hardness Test Water Volume - crude test Soap drops - crude test Grains/gallon GPG of Water Hardness ppm mg/L Water hardness in parts per million in milligrams per liter Softness of the Water 12 oz 10 0 - 1 0-17.1 Very Soft 20 1 - 3.5 17.1 - 60 Slightly Hard 30 3.5 07 . Micro hardness testing involves forcing a diamond indenter with a specific geometry into the surface of a test piece under a small load, then using a microscope to measure the resulting indentation to determine the hardness; there are three main types of tests that differ by the indenter shape and how indentation size is measured; micro hardness testing is useful . 2. Definition of Hardness : Hardness is the property of a material that enables it to resist plastic deformation usually by penetration.However the term hardness also refer to resistence bending, scratching, abrasion or cutting. This test also performed when the material’s hardness beyond the range of Brinell’s hardness. Hardness is dependent on ductility, elastic . 2. Brinell hardness test Brinell Balls Table 1 dia and tolerance of Brinell hardness ball Sr. no Ball dia, mm Tolerance, mm 1 10 ±0.005 2 5 ±0004 3 2.5 ±0.003 4 2 ±0.003 5 1 ±0.003 Measuring Device The divisions of the micro .

3. Brinell Hardness Test The brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on the material test pieces. It is one of several definitions of hardness . BREAKING TEST ( HARDNESS) The breaking test is designed as a method for measuring the brittleness of suppository. 1-The suppository is placed in the instrument. 2- Add 600 g; leave it for one min. (use a stop watch). 3- If .

28. The Shore (Durometer) test provides an empirical hardness value that doesn't correlate to other properties or fundamental characteristics. Shore Hardness, using either the Shore A or Shore D scale, is the preferred method for rubbers/elastomers and is also commonly used for 'softer' plastics such as polyolefins, fluoropolymers, and vinyls. 5. Brinell Hardness Test • The Brinell hardness testing consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball(10mm) subjected to a load of 500 to 3000 kg for 10 to 30 second. • The full load (3000 Kg) is normally applied for iron and steel for 10 to 15 seconds • The load can be reduced to 1500 kg or 500 kg for 30 second to avoid . 1. Universitas 17 Agustus 1945, Surabaya, 2014 Rohmad Putra 411306092 1 Nama : Rohmad Putra Nbi : 411306092 Kelas : C Rumus Dari Metode Hardness Test Metode Brinnel, Rockwell, Vikers Dan Micro Hardness 1. Metode Brinnel (HB / BHN) Pengujian kekerasan dengan metode Brinnel bertujuan untuk menentukan kekerasan suatu material . 3. Qualification Qualification is described as the action of proving and documenting that any premises, systems and items of equipment work correctly and actually leads to the expected results. Purpose To document the original installation conditions and establish that the equipment is suitable for the task it is assigned. The protocols must be organised, easy to .

11. About the experiment The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to15 seconds. The two diagonals of the indentation left . 2)HARDNESS It is defined as the force required to break a tablet in a diametric compression test. Hardness is an unofficial test. Hardness is measured by 1)Monsanto tester. 2)Pfizer. 3) Strong-Cobb tester 4)erweka 5)scheuniger Conventional tablets hardness : 2.5- 5 kg/cm2 Dispersible/ chewable tablets hardness: 2.25- 2.5 kg/cm2 Extended release .

7. Hardness It is the load required to crush the tablet when placed on its edge. It determine the need for pressure adjustments on the tableting machine. Hardness can affect the disintegration. So if the tablet is too hard, it may not disintegrate in the required period of time. And if the tablet is too soft, it will not withstand the handling during subsequent processing . 11. HARDNESS TEST Tablets require a certain amount of strength or hardness during transportation and handling. Generally, greater compression force is applied, harder the tablets, Certain tablets such as lozenges or buccal tablets are intended to dissolve slowly, so they are made intentionally hard. For tablets meant for immediate release, they are intentionally . Predict in vivo drug release profiles. Test is intended for a capsule or Tablet. Condition maintained: Temperature: 37 ± 0.5°C Speed: 25-150 rpm 10. BASKET TYPE: Vessel is cylindrical Hight: 100-210mm Inside diameter: 98-106mm Basket position: the distance between the inside of bottom vessel & basket maintained at 25 ± 2mm. 2. Rockwell hardness test K = constant, for C scale it is 0.2 and for B scale it is 0.26 h = depth of impression in mm Hence the formulae for HRc = 100 – e where e = h/0.2 And for HRB = 130 – e where e h/0.26 Scales and values The most common indenter type is a diamond cone ground at 120 degrees for testing hardened steels and carbides. . Softer materials are .

types of hardness testing methods

Catch up on old episodes of 154 - Ian Neves & Humberto Matos [+Paulo Galo e Chavoso da Usp]. All of your favorites, now on Zeno.

hardness test slideshare|hardness test procedure